ericj96

VCA Member

Gen 4 & 5 Performance Well Hidden, Greg Good Heads Dyno, Cam Specs

I have been through a series of mods to my 1996 RT10 and would like to share some technical observations that may be helpful to those that would like to bring their late 90s Vipers up to gen 4-gen 5 straight line performance standards without sacrificing the cars drivability and idle characteristics. In short those that want their great looking collectable car to run like a gen four or gen five and almost pass for stock.

Heads:

Below is the dyno result from the installation of a set of Greg Good heads with roller rockers. The valves are 2.02/1.58 with 69.5 cc chambers after being milled. This yielded about a 10.2 to one mechanical compression ratio on my gen one.

Mod Set 1=Smooth Tubes & Filters, 3" borla exhaust from the manifold flange back

Mod Set 2= Smooth Tubes & Filters, 3" Borla exhaust from the manifold flange back, with Greg Good Heads and 1.7 Harland Sharp Rockers

Both data sets have stock throttle bodies, intake, cam and exhaust manifolds.

..........MOD1....MOD2

RPM T....HP.. ...T.....HP

1600 ................423 129

1800 ................424 145

2000 406 155 ..425 162

2200 412 173.. 424 178

2400 410 187.. 422 193

2600 417 206.. 441 218

2800 420 224.. 450 240

3000 420 240.. 452 258

3200 432 263.. 461 281

3400 442 286.. 479 310

3600 461 316.. 492 337

3800 460 333.. 491 355

4000 455 347.. 495 377

4200 455 364.. 502 401

4400 451 378.. 495 415

4600 438 384.. 490 429

4800 433 396.. 485 443

5000 420 401.. 469 446

5200 401 397.. 451 447

5400 383 394.. 439 451

5600 365 389.. 418 446

5800 335 370.. 390 431

6000 ................360 411

The entire torque curve lifted at least 12 ft pounds from 1500 rpm all the way out. Average increase in rotational force was about 9% at all points. Peak RW torque was up 40 ft lbs and peak horse power was up 50 RWHP. Peak HP and torque moved up 400 RPM. The heads flowed 285 cfm at 575 lift and 225 at 550 lift respectively. Point being have Greg Good rework your heads.

Picking the right cam:

I see it over and over on the net. People recommending these massive cams in our cars and then I go over and look at our long narrow runner manifold that wants to go completely out of resonance by 5750 RPM? There is an old adage in engine building that says “help your engine do what it wants to do and it will love you for it”. These massive long stroke engines with long runners want to build lots of mid range torque first and foremost. You can force the motor to peak in the 5500-6200 RPM range but you don’t pick much NET area under the curve for your efforts.

When I went to pick my cam I needed to know what was typical of the late 90s viper engines so I sent off some material to Comp Cams to be “cam doctored” these were the results:

Stock Gen I Viper Cam

Duration at .006” lift intake = 285 deg

Duration at .006” lift exhaust = 278 deg

Duration at .050” intake = 218 deg

Duration at .050” exhaust = 212 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .308

Exhaust lift at lobe= .291

Intake closing event was 77 deg after bottom dead center----translates these cams do not have the exact same lift and close rates on the lobe if what comp cams is reading is correct.

708 Gen II Cam 1996 to 1999

Duration at .006” lift intake = 288 deg

Duration at .006” lift exhaust = 296 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 230 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .321

Exhaust lift at lobe= .321

It has been my experience that on fixed timing (non direct injection) engines running pump gas you are asking for predetination problems when your cranking cylinder pressure gets into the 190s. Most tuners and the new Gen 4 and later engines are running without issue 10.2 to one compression so that’s the ratio I picked. The next question was what is the ideal intake valve closing point on the cam to give me my target cranking cylinder pressure of 182? The cranking pressure models suggest that 74 degrees after bottom dead center will yield a 182 psi cranking cylinder pressure.

Note that both the above listed factory cams have an intake duration of about 220 deg at .050” lift and a 117 intake center line. This late lobe center is the child of the long runners and the need for late valve closing as the column of incoming air is still trying to get into the cylinder long after the piston is on its way back up. This is black magic got to test it to get it right kind of research so I left the cam lobe centers in the same location Dodge did in the 90s before lobe centers were moved to keep the tree huggers happy in 2000.

Based on this I went looking for intake lobes and found the following:

Comp Cams Dodge Viper Camshaft Single pattern with 3051 lobes:

Duration at .006” lift intake = 274 deg

Duration at .050” intake = 220 deg

Duration at .200” intake = 134 deg

Intake Center line = 117 deg

Intake lift at lobe = .320

Intake closing event was 74 deg after bottom dead center

This is a faster than stock acting lobe that was developed for offshore marine racing engines that need to survive endless duty at high RPM and have excellent longevity characteristics. This cam has more area under the lift curve than the 708 but gave me a much higher average cranking cylinder pressure ranging from 181 to 189 psig depending on the cylinder bank and razor sharp throttle response. The engine now produces 550 RWT and I attribute some of this to increased area under the curve and high cylinder pressure created by a close to ideal intake valve closing point for the application.

I was so paranoid about losing my stock idle characteristics I just went with the same exhaust lobe as I did on the intake on a 114 lobe center angle. This profile made a wonderful gen one improvement cam. Its total specs are listed below.

Comp Cams Dodge Viper Camshaft Single pattern with 3051 lobes:

Duration at .006” lift intake = 274 deg

Duration at .006” lift exhaust = 274 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 220 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .320

Exhaust lift at lobe= .320

Intake closing event was 74 deg after bottom dead center.

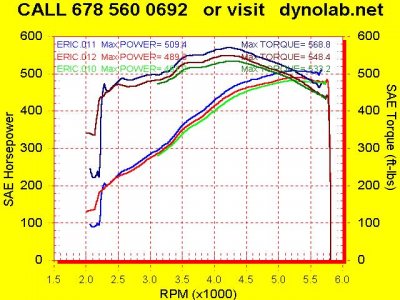

With the new 220 220 114 gen one replacement cam, Greg Good Heads, Harland Sharp Roller Rockers, 1.75 Tri Y headers, 3” Borla exhaust (bullet mufflers in the place of cats), 65mm throttle bodies, aluminum flywheel and ASP under drive pulley the car pulls the following rear wheel numbers on the Dynojet on a routine basis. The blue line on the attached dyno chart is with a completely cold motor and is not a reasonable representation of the motors characteristics in operation.

RPM…….. T....HP..

1600… 430…130

1800… 435…150

2000… 440…167

2200… 440…184

2400… 465…212

2600… 470…232

2800… 465…247

3000… 485…277

3200… 490…298

3400… 505…326

3600… 530…363

3800… 533…385

4000… 545…415

4200… 551…440

4400… 545…456

4600… 540…472

4800… 525…480

5000… 510…485

5200… 495…490

5400… 475…488

5600… 450…480

5800… 430…470

6000… 395…450

When the car pulled through tech at Atlanta Dragway or Atlanta Motor Speedway for Friday Night Drags the tech guys assumed it was a stock mid 90s viper with exhaust work. In the fall and spring with 600-700 DA a off idle launch and no burn out it turns the following if I don’t spin the tires, bog or miss a gear:

Eight Mile

60 ft…..1.85

330 ft… 4.94

1/8[SUP]th[/SUP]…. 7.45 at 99 mph

Quarter Mile

60 ft …..1.84

330 ft….4.92

1/8[SUP]th[/SUP]…..7.47 at 98 mph

1000….9.64

1/4[SUP]th[/SUP]….11.50 at 123 mph

This car runs with cars pulling better RWHP numbers because for a mild NA car its midrange is crushing. There is no “recovering from an up shift”.

If I had a gen two motor and wanted to mimic and replace the 708 but with more rotational force everywhere I would have used the same intake lobe but with the Comp Cam Magnum Marine exhaust lobe 3052 with the following specs:

Comp Cams Dodge Viper Camshaft Dual pattern with 3051/3052 lobes:

Duration at .006” lift intake = 274 deg

Duration at .006” lift exhaust = 284 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 230 deg

Duration at .200" intake =134 deg

Duration at .200" exhaust =142 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .320

Exhaust lift at lobe= .320

Intake closing event was 74 deg after bottom dead center.

If you have not purchased a Viper Yet but are thinking about an early model I would keep in mind that 1996 was the first year of the easy to program OBD2 computer. I would also consider that 1999 was the last year for forged motors with a PCM that did not process any data from the second set of oxygen sensors. Do NOT use cheap Federal Mogul or Speed Pro roller lifters as you may have the chance to replace them twice because they would not pump up. ;-(

Hope some of this helps someone.

I have been through a series of mods to my 1996 RT10 and would like to share some technical observations that may be helpful to those that would like to bring their late 90s Vipers up to gen 4-gen 5 straight line performance standards without sacrificing the cars drivability and idle characteristics. In short those that want their great looking collectable car to run like a gen four or gen five and almost pass for stock.

Heads:

Below is the dyno result from the installation of a set of Greg Good heads with roller rockers. The valves are 2.02/1.58 with 69.5 cc chambers after being milled. This yielded about a 10.2 to one mechanical compression ratio on my gen one.

Mod Set 1=Smooth Tubes & Filters, 3" borla exhaust from the manifold flange back

Mod Set 2= Smooth Tubes & Filters, 3" Borla exhaust from the manifold flange back, with Greg Good Heads and 1.7 Harland Sharp Rockers

Both data sets have stock throttle bodies, intake, cam and exhaust manifolds.

..........MOD1....MOD2

RPM T....HP.. ...T.....HP

1600 ................423 129

1800 ................424 145

2000 406 155 ..425 162

2200 412 173.. 424 178

2400 410 187.. 422 193

2600 417 206.. 441 218

2800 420 224.. 450 240

3000 420 240.. 452 258

3200 432 263.. 461 281

3400 442 286.. 479 310

3600 461 316.. 492 337

3800 460 333.. 491 355

4000 455 347.. 495 377

4200 455 364.. 502 401

4400 451 378.. 495 415

4600 438 384.. 490 429

4800 433 396.. 485 443

5000 420 401.. 469 446

5200 401 397.. 451 447

5400 383 394.. 439 451

5600 365 389.. 418 446

5800 335 370.. 390 431

6000 ................360 411

The entire torque curve lifted at least 12 ft pounds from 1500 rpm all the way out. Average increase in rotational force was about 9% at all points. Peak RW torque was up 40 ft lbs and peak horse power was up 50 RWHP. Peak HP and torque moved up 400 RPM. The heads flowed 285 cfm at 575 lift and 225 at 550 lift respectively. Point being have Greg Good rework your heads.

Picking the right cam:

I see it over and over on the net. People recommending these massive cams in our cars and then I go over and look at our long narrow runner manifold that wants to go completely out of resonance by 5750 RPM? There is an old adage in engine building that says “help your engine do what it wants to do and it will love you for it”. These massive long stroke engines with long runners want to build lots of mid range torque first and foremost. You can force the motor to peak in the 5500-6200 RPM range but you don’t pick much NET area under the curve for your efforts.

When I went to pick my cam I needed to know what was typical of the late 90s viper engines so I sent off some material to Comp Cams to be “cam doctored” these were the results:

Stock Gen I Viper Cam

Duration at .006” lift intake = 285 deg

Duration at .006” lift exhaust = 278 deg

Duration at .050” intake = 218 deg

Duration at .050” exhaust = 212 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .308

Exhaust lift at lobe= .291

Intake closing event was 77 deg after bottom dead center----translates these cams do not have the exact same lift and close rates on the lobe if what comp cams is reading is correct.

708 Gen II Cam 1996 to 1999

Duration at .006” lift intake = 288 deg

Duration at .006” lift exhaust = 296 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 230 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .321

Exhaust lift at lobe= .321

It has been my experience that on fixed timing (non direct injection) engines running pump gas you are asking for predetination problems when your cranking cylinder pressure gets into the 190s. Most tuners and the new Gen 4 and later engines are running without issue 10.2 to one compression so that’s the ratio I picked. The next question was what is the ideal intake valve closing point on the cam to give me my target cranking cylinder pressure of 182? The cranking pressure models suggest that 74 degrees after bottom dead center will yield a 182 psi cranking cylinder pressure.

Note that both the above listed factory cams have an intake duration of about 220 deg at .050” lift and a 117 intake center line. This late lobe center is the child of the long runners and the need for late valve closing as the column of incoming air is still trying to get into the cylinder long after the piston is on its way back up. This is black magic got to test it to get it right kind of research so I left the cam lobe centers in the same location Dodge did in the 90s before lobe centers were moved to keep the tree huggers happy in 2000.

Based on this I went looking for intake lobes and found the following:

Comp Cams Dodge Viper Camshaft Single pattern with 3051 lobes:

Duration at .006” lift intake = 274 deg

Duration at .050” intake = 220 deg

Duration at .200” intake = 134 deg

Intake Center line = 117 deg

Intake lift at lobe = .320

Intake closing event was 74 deg after bottom dead center

This is a faster than stock acting lobe that was developed for offshore marine racing engines that need to survive endless duty at high RPM and have excellent longevity characteristics. This cam has more area under the lift curve than the 708 but gave me a much higher average cranking cylinder pressure ranging from 181 to 189 psig depending on the cylinder bank and razor sharp throttle response. The engine now produces 550 RWT and I attribute some of this to increased area under the curve and high cylinder pressure created by a close to ideal intake valve closing point for the application.

I was so paranoid about losing my stock idle characteristics I just went with the same exhaust lobe as I did on the intake on a 114 lobe center angle. This profile made a wonderful gen one improvement cam. Its total specs are listed below.

Comp Cams Dodge Viper Camshaft Single pattern with 3051 lobes:

Duration at .006” lift intake = 274 deg

Duration at .006” lift exhaust = 274 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 220 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .320

Exhaust lift at lobe= .320

Intake closing event was 74 deg after bottom dead center.

With the new 220 220 114 gen one replacement cam, Greg Good Heads, Harland Sharp Roller Rockers, 1.75 Tri Y headers, 3” Borla exhaust (bullet mufflers in the place of cats), 65mm throttle bodies, aluminum flywheel and ASP under drive pulley the car pulls the following rear wheel numbers on the Dynojet on a routine basis. The blue line on the attached dyno chart is with a completely cold motor and is not a reasonable representation of the motors characteristics in operation.

RPM…….. T....HP..

1600… 430…130

1800… 435…150

2000… 440…167

2200… 440…184

2400… 465…212

2600… 470…232

2800… 465…247

3000… 485…277

3200… 490…298

3400… 505…326

3600… 530…363

3800… 533…385

4000… 545…415

4200… 551…440

4400… 545…456

4600… 540…472

4800… 525…480

5000… 510…485

5200… 495…490

5400… 475…488

5600… 450…480

5800… 430…470

6000… 395…450

When the car pulled through tech at Atlanta Dragway or Atlanta Motor Speedway for Friday Night Drags the tech guys assumed it was a stock mid 90s viper with exhaust work. In the fall and spring with 600-700 DA a off idle launch and no burn out it turns the following if I don’t spin the tires, bog or miss a gear:

Eight Mile

60 ft…..1.85

330 ft… 4.94

1/8[SUP]th[/SUP]…. 7.45 at 99 mph

Quarter Mile

60 ft …..1.84

330 ft….4.92

1/8[SUP]th[/SUP]…..7.47 at 98 mph

1000….9.64

1/4[SUP]th[/SUP]….11.50 at 123 mph

This car runs with cars pulling better RWHP numbers because for a mild NA car its midrange is crushing. There is no “recovering from an up shift”.

If I had a gen two motor and wanted to mimic and replace the 708 but with more rotational force everywhere I would have used the same intake lobe but with the Comp Cam Magnum Marine exhaust lobe 3052 with the following specs:

Comp Cams Dodge Viper Camshaft Dual pattern with 3051/3052 lobes:

Duration at .006” lift intake = 274 deg

Duration at .006” lift exhaust = 284 deg

Duration at .050” intake = 220 deg

Duration at .050” exhaust = 230 deg

Duration at .200" intake =134 deg

Duration at .200" exhaust =142 deg

Intake Center line = 117 deg

Angle between lobes = 114 deg

Intake lift at lobe = .320

Exhaust lift at lobe= .320

Intake closing event was 74 deg after bottom dead center.

If you have not purchased a Viper Yet but are thinking about an early model I would keep in mind that 1996 was the first year of the easy to program OBD2 computer. I would also consider that 1999 was the last year for forged motors with a PCM that did not process any data from the second set of oxygen sensors. Do NOT use cheap Federal Mogul or Speed Pro roller lifters as you may have the chance to replace them twice because they would not pump up. ;-(

Hope some of this helps someone.

Attachments

Last edited: